Accelerator Project: Advancing High-Performance Materials for Extreme Energy Environments

Posted on

Dr. Jamie Hogan (left) and Dr. Mostafa Yakout (right) are interviewed for the Accelerator Project Series

New energy technologies bring new challenges, including the crucial question of whether we have the right materials and manufacturing methods to process and can leverage them safely. Long-term exposure to hydrogen can make otherwise robust materials brittle, while new nuclear systems require specially-designed materials to ensure safety during operations. Fortunately, research at Future Energy Systems (FES) is helping change manufacturing systems and materials, helping these new energy systems become a reality in Alberta and Canada.

At the heart of many of this century’s biggest leaps in tools and technological developments is advanced manufacturing, the engineering process that leverages the newest technologies, processes, and materials to create engineered products that push boundaries. Advanced materials manufacturing focuses on the structure and composition of materials, leveraging multi-scale modelling to more precisely and efficiently create structures that hold up better in the long run under extreme environments.

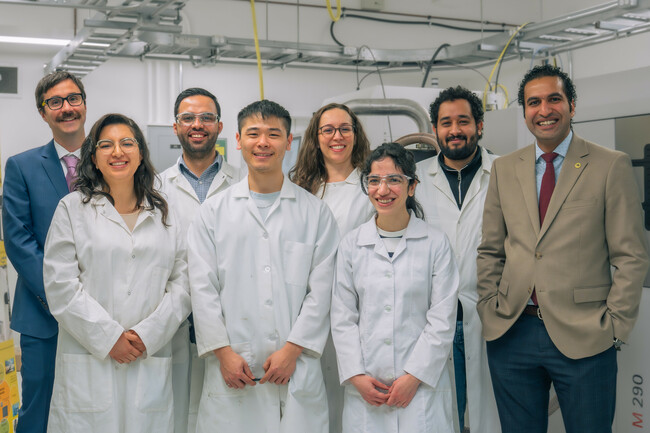

At the University of Alberta, Dr. Mostafa Yakout and Dr. Jamie Hogan are collaborating to develop state-of-the-art process-driven manufacturing solutions for advanced, high-performance materials. The pair are linking advanced additive manufacturing (a type of advanced manufacturing that allows for complex geometries for increased multi-functionality) and high-performance materials to design structures and surface coatings that can withstand extreme environments defined by out-of-the-ordinary conditions such as high-pressure, high-temperature, high-shock impact, and high-radiation. Such conditions are often found in specialized industries like energy, aerospace, and defence.

By working with materials composed of ultra-high-strength alloys with high-temperature corrosion-resistance properties, they’re developing materials and coatings that can withstand the extremes of nuclear reactors and hydrogen fuel systems. In the long term, their work supports Canada’s innovation in these sectors, especially for energy in Alberta.

Advancing Materials with Collaboration

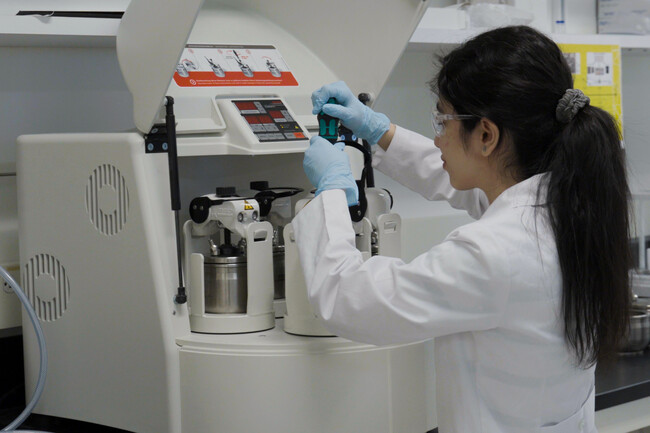

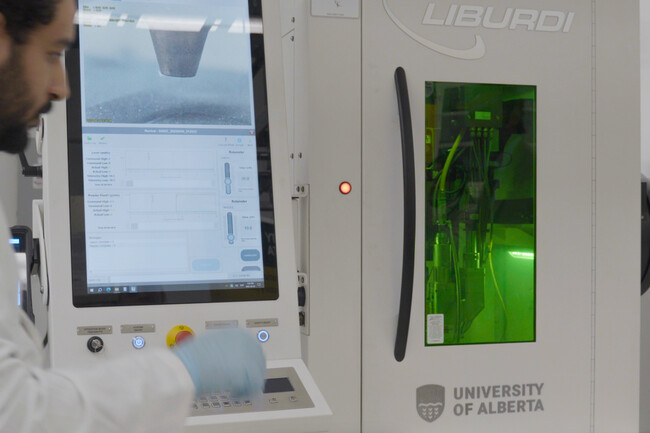

Professor Yakout runs the Alberta Next-Generation Additive Manufacturing (ANGAM) lab, which specializes in the development and optimization of process-driven solutions for additive manufacturing (AM) of next-generation materials, such as high-temperature corrosion-resistant materials, ultra-high-strength alloys, high-performance metallic and ceramic materials, and alloys containing rare-earth metals and critical minerals. His team of experts enhances and refines the manufacturing process for high-performance materials. They manufacture made-in-Canada materials and coatings in-house in Alberta.

The ANGAM lab works in tandem with Professor Hogan and his research team at the Centre for Defence: Advanced Materials (CDAM) lab. Made up of computer modelling experts, the CDAM team specializes in microstructure-based designs and testing and can recreate extreme conditions to test and retest how the materials function.

“It’s a team effort,” says Jamie. “My students work with exact variables—temperature, rate of pressure change, the functional requirements of a part that inform testing under defence and energy conditions, which is necessary for Mostafa’s group.”

“We work together in both the manufacturing and testing stages,” Mostafa continues. “The results of testing help us adjust the manufacturing process. We send Jamie’s group data collected in-situ (on site) during the manufacturing process to adjust their simulation models.”

Working with different scales, from the atomic level up to the structural level, Jamie’s lab uses predictive modelling to get a better picture of how materials are affected by the intense conditions.

“Most of what we do happens at the sub-grain level,” Jamie explains. “But we can only see and measure the effects that happen at the structural level. That’s where computer modelling and validation come in. We bridge that gap between lab-scale and the real world to make sure the materials meet the necessary standards.”

Recipes for the Materials of Tomorrow

It can take years, if not decades, to correctly and safely develop the advanced manufacturing process protocol and procedures for high-performance materials suitable for future energy systems. Researching, testing, and modelling can be time-consuming, rigorous, and expensive, as each step is repeated at the lab scale, then again at the commercial scale with support from industry partners. But every step is essential to ensuring safety and success in a high-stakes environment.

“There’s no room for error in what we do,” says Mostafa. “People use the phrase ‘it’s not rocket science,’ but in our case, it kind of is. We’re working on materials for nuclear energy systems, aerospace components, and more complex and potentially dangerous systems. We can’t afford to fail when it comes to developing these materials.”

The longer timeline includes training personnel. Graduate and post-graduate researchers spend years learning the ins and outs of advanced materials manufacturing, acquiring the knowledge and skills they need to work with these systems in the next stages of their careers. By working directly with industry partners, students also build future connections for themselves.

“Most of my students have gone on to work with our industry collaborators,” says Jamie. “They graduate with experience in advanced research and real-world application, which is a valuable opportunity for their careers.”

“We encourage our students to see every problem from multiple perspectives,” Mostafa adds. “Academic, engineering, business, and communication. That’s how innovation truly happens.”

After identifying, developing, and solidifying the process for manufacturing high-performance materials, the final step is developing the standards and qualifications for the materials, processes, and post-processing procedures. Research results are shared and reviewed with industry collaborators, national labs, and standards organizations for potential incorporation into the policies and standards that govern safety for materials and coatings in extreme environments.

Applications & Next Steps

Research questions are often shaped around industry needs, especially when researchers are approached to help solve a particular technological challenge. One application for Jamie and Mostafa’s advanced materials manufacturing work is hydrogen production. With support from the Edmonton Region Hydrogen Hub, their materials and coatings will improve the efficiency of methane pyrolysis reactors, which produce hydrogen from natural gas.

“We’re working to solve hydrogen embrittlement, carbon clogging, and metal dusting challenges occurring in the reactors that produce hydrogen from methane pyrolysis,” explains Jamie.

Mostafa and the ANGAM lab are also lending their research work to the conditions found in small modular reactors (SMRs). Mostafa and his team leverage laser additive manufacturing processes for high-temperature materials, and are the only lab in Western Canada with the equipment to do so. They aim to enhance the performance and lifetime of these nuclear SMRs and advanced reactors with additive manufacturing of corrosion-resistant stainless steels and superalloys.

Moving forward, Jamie and Mostafa are open to expanding their scope and working with more sectors to solve challenges with additive manufacturing for high-performance materials.

“We’re always looking to collaborate with new industries,” says Mostafa. “We’ve just started work on biomedical and dental materials, which have different challenges, but the same underlying need: materials that won’t fail when it matters most.”

Through their partnership, Mostafa and Jamie are not only developing the next generation of materials but also preparing the next generation of researchers to take them further. Advanced materials are the backbone of future technologies in Alberta and Canada, especially in extreme environments where safety, durability, and precision are non-negotiable.

Watch Jamie and Mostafa's Accelerator Project Feature on our YouTube channel: Advancing Manufacturing for Extreme Energy Environments.

This story is part of Future Energy System’s Accelerator Project Series. To stay up to date with this series, subscribe to our monthly newsletter and follow FES on social media.

Further Reading:

Alberta Next-Generation Additive Manufacturing (ANGAM) Lab

Centre for Applied Research in Defence and Dual-use Technologies (CaRDD-Tech).

Centre for Defence: Advanced Materials (CDAM)